-

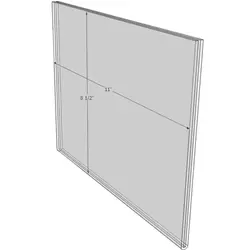

10″ x 8″ Landscape

Price range: $6.34 through $9.62 Add To Cart This product has multiple variants. The options may be chosen on the product page -

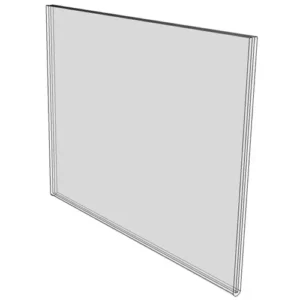

11″ x 14″ Portrait

Price range: $13.31 through $17.57 Add To Cart This product has multiple variants. The options may be chosen on the product page -

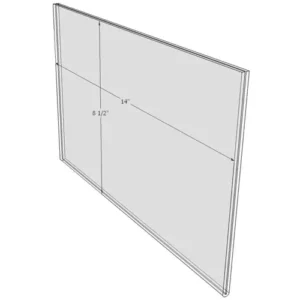

11″ x 8.5″ Landscape

Price range: $7.16 through $11.25 Add To Cart This product has multiple variants. The options may be chosen on the product page -

12″ x 9″ Landscape

Price range: $9.23 through $12.61 Add To Cart This product has multiple variants. The options may be chosen on the product page -

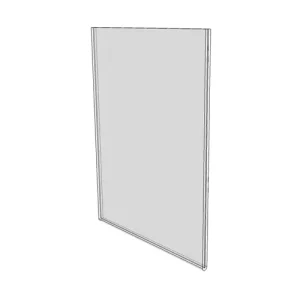

14″ x 8.5″ Landscape

Price range: $9.11 through $13.45 Add To Cart This product has multiple variants. The options may be chosen on the product page -

2.5″ x 3.5″ Portrait

Price range: $1.98 through $3.61 Add To Cart This product has multiple variants. The options may be chosen on the product page -

3.5″ x 2.5″ Landscape

Price range: $1.98 through $3.61 Add To Cart This product has multiple variants. The options may be chosen on the product page -

3.5″ x 5.5″ Portrait

Price range: $2.44 through $3.21 Add To Cart This product has multiple variants. The options may be chosen on the product page

Explore Our

Most Popular Products

Innovative Custom Plastics, Engineered for You.

Advertising, marketing and promotion are essential for any successful business and are often achieved or enhanced by quality signage and displays. Your goal may be to highlight specials, present information about your business, or list future events. Whatever the case, the signs and displays you use become an important part of relaying information that is essential to the maintenance and growth of your business.

You can trust the quality products you will receive from Plastics Plus. We give our customers exactly what our name implies: plastics, such as sign holders, displays, brochure holders and more. Along with our products, we offer exceptional customer service with the personal touch that only a smaller company can offer. Virtually all of our quality products are made in the USA at our fabrication facility in Bismarck North Dakota.

Discover Plastics Plus

We fabricate items from many kinds of plastics including acrylic, polycarbonate, PVC, PETG, ABS and HDPE. This allows Plastics Plus to fabricate items for many different uses. Valuing all customers, we are able to accommodate just about anyorder; from customers requiring a few pieces to those who need several thousand.

Material Overview

Plastic fabrication is the process of converting raw plastic materials into finished products using various techniques. It is a versatile and essential part of modern manufacturing, enabling the production of a diverse array of durable, lightweight, and cost-effective items for industries ranging from automotive and medical to consumer goods and packaging. The specific fabrication method used depends on the type of plastic material, the product’s design and functional requirements, and the desired production volume.

Acrylic plastic, also known as PMMA (polymethyl methacrylate) or Plexiglass, is a thermoplastic material. It comes in clear, tinted, and many other colors. It’s a synthetic polymer derived from petroleum and natural gas, commonly used as an alternative to glass due to its strength and clarity.

Polycarbonate is a transparent, durable thermoplastic known for its high impact resistance and strength. It’s a group of polymers containing carbonate groups in their structure and is widely used in various applications, including safety goggles, bulletproof materials, and various outdoor sheeting materials.

Foam PVC is a lightweight, rigid, and durable material with a closed-cell structure, offering benefits like dent and scratch resistance, chemical resistance, and heat formability. It is commonly used for signage, displays, and other applications where a durable, printable, and easily shaped material is needed.

Coroplast is a brand name, most often used to refer to corrugated plastic sheets made from polypropylene. These sheets are known for their lightweight, durable, and weather-resistant qualities, making them popular for signage, packaging, and various other applications.

Also known as polystyrene, is a versatile thermoplastic polymer derived from styrene, a colorless, flammable liquid. It’s a common plastic used in various applications due to its affordability, ease of processing, and ability to be molded into various forms. Styrene can be solid, foamed, or in film form, and is known for its lightweight and rigid properties.

Polyethylene Terephthalate Glycol, a thermoplastic polyester known for its strength, durability, and ease of use in 3D printing and other manufacturing applications. It’s essentially a modified version of PET (Polyethylene Terephthalate), with the addition of glycol, which enhances its properties.

ABS plastic, or acrylonitrile butadiene styrene, is a tough, versatile thermoplastic polymer known for its strength, durability, and impact resistance. It’s commonly used in various applications due to its ability to be easily molded, painted, and finished

High Density Poly Ethylene (HDPE) is a thermoplastic polymer made from petroleum. As one of the most versatile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping. Known for its outstanding tensile strength and large strength-to-density ratio, HDPE plastic has a high-impact resistance and melting point.

UHMW is a type of thermoplastic polyethylene with extremely long chains, resulting in high durability, low friction, and resistance to wear and impact. It’s a versatile material used in a wide range of industrial and consumer applications.

Nylon is a family of synthetic polymers known for their strength, elasticity, and wear resistance. Black nylon is frequently used in applications requiring durability, wear resistance, and resistance to chemicals and moisture, such as in gears, bearings, insulators, and various industrial components.

Green oil-filled nylon is a type of nylon engineering plastic that has been modified with internal lubrication, typically oil, to enhance its performance in bearing and wear applications. This modification results in a self-lubricating material with reduced friction and wear resistance, making it suitable for applications where traditional lubrication is difficult or undesirable